Cutting Time and Cost with FEA and Optimized Design

October 31, 2025The pace of manufacturing innovation today is fast, and the timelines are tight. Every engineer and production manager knows the severe financial pressure that comes with launching a new product or process.

Global competition demands perfect efficiency, leaving no room for wasted time or resources. When profit margins are constantly scrutinized, uncompetitive cost structures and lagging productivity are risks no firm can afford. Investor expectations, unpredictable tariffs, and escalating input costs only amplify this pressure, making meticulous resource management absolutely essential.

That is why finite element analysis (FEA) and optimized design are no longer optional—they are the essential tools for achieving necessary cost reduction and securing market leadership.

From our base in Farmington Hills, MI, and our support in Windsor, ON, DSC provides this critical path forward by moving problem-solving from the factory floor to the digital realm.

The Pressures on Production

The margin for error in manufacturing is shrinking every year. Unstable supply chains, fluctuating material costs, and global trade policies increase risk, making efficient production non-negotiable.

For many companies, even a small disruption—like a component delay or the unexpected failure of a new piece of equipment—can trigger a massive chain reaction, jeopardizing contracts and profitability. Success depends entirely on finding efficiencies, validating performance, and achieving optimization before production ever begins.

We see this pressure strongly affecting Ontario manufacturing, which must innovate quickly to compete with international markets that often have lower labor costs. When designs are outdated or overly complicated, they inevitably slow down the line, require excessive material, and increase long-term operational costs.

This productivity gap makes it harder for North American companies to scale and win international bids. To stay competitive, manufacturers must adopt advanced technologies that enable engineering precision from the very start.

Understanding FEA

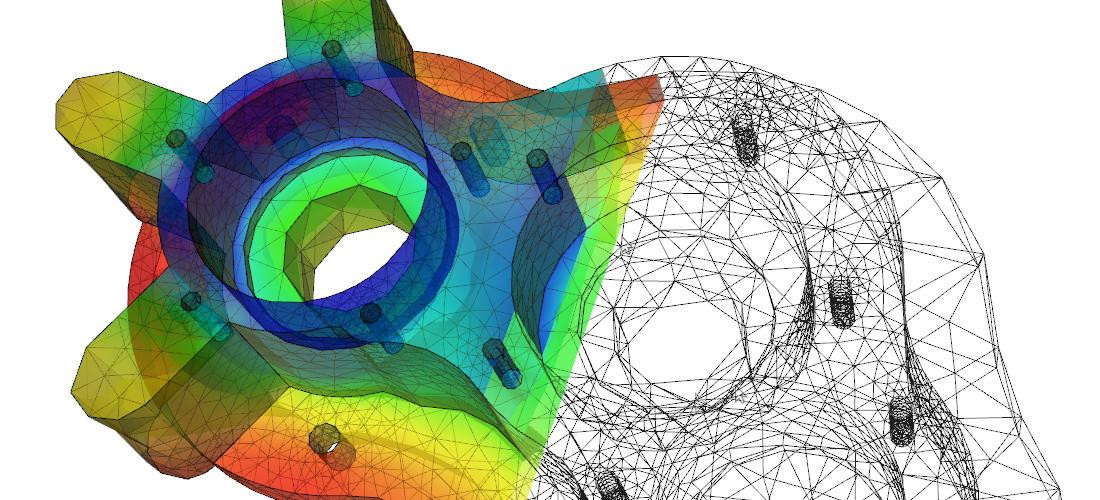

Finite element analysis is a powerful computational tool that simulates how a physical product behaves under stress. It works by breaking down a complex structure—like a machine frame, a crane hook, or a packaging system—into many smaller, manageable pieces, or elements.

The software then applies real-world conditions like static and dynamic force, heat, vibration, or fluid flow to these elements, calculating the results across the entire structure. This process provides a clear picture of performance in scenarios that would be impossible or unsafe to test physically, such as crashworthiness or fatigue life under millions of cycles.

The final goal of this process is optimized design. This means finding the single most efficient design that uses the least amount of material and time while maintaining superior strength, safety, and performance.

Beyond simply minimizing material use, optimization ensures a product has the longest possible lifespan and maximum reliability. An effective FEA simulation allows engineers to stop guessing and start knowing how their designs will truly hold up in operation.

Replacing Prototypes with Precision

Traditionally, engineers had to build multiple, expensive, physical versions for testing. This long, costly cycle of build, test, break, and rebuild added weeks or months to a project's timeline—the heart of the prototype design problem.

Imagine needing to confirm a new conveyor bracket can handle extreme loads; without FEA, you build ten brackets, load them until they fail, and only then do you start the expensive redesign process.

The modern approach is fundamentally different. FEA simulation allows engineers to test countless design iterations virtually, often overnight. If a weak point or stress concentration is found, the design is adjusted in the software and re-tested instantly.

This dramatically shortens the development cycle and cuts out unnecessary phases of physical prototype design. It also minimizes the environmental footprint associated with wasting materials on failed tests.

This virtual testing directly translates to significant cost reduction in multiple, key areas:

Material Savings: FEA simulation helps identify areas where material can be safely removed or reduced without compromising strength, a process called topology optimization. This not only reduces purchasing costs but also minimizes the ongoing weight and energy requirements of the final product.

Rework Avoidance: Flaws, stress points, or potential failure risks are found on the computer long before expensive materials are purchased or a single piece of steel is cut. This preemptive identification saves money, avoids late-stage schedule delays, and protects against costly field failures after launch.

Tooling: By finalizing a manufacturing-optimized design early, companies avoid costly tooling redesigns that plague traditional prototype design schedules. New tooling can take weeks or months to manufacture, making this delay one of the most expensive hidden costs in product development.

The time saved by skipping physical prototype design cycles translates directly to faster product launches, giving you a strong competitive advantage in the market and ensuring that your product reaches the customer while demand is highest.

DSC’s Regional Expertise and Comprehensive Support

At DSC, we understand that great engineering requires more than just one tool. We provide not just FEA simulation, but a full suite of services including industrial engineering, supply chain optimization, and process simulation. Our holistic approach ensures that every design solution fits perfectly into your larger manufacturing process.

For example, the results from an FEA model are often fed directly into a process simulation to confirm not just that a machine is strong enough, but that it moves fast enough to meet production targets.

Our specialization in the Canadian market, especially serving Ontario manufacturing, is a major asset. We offer crucial support such as Technical Standards and Safety Authority (TSSA) document preparation and Pre-Start Health and Safety Reviews (PSRs).

This guarantees that your optimized designs are not only efficient but also compliant with local regulations, preventing costly production shutdowns or legal liabilities. With a team of over 300 professionals and a history stretching back to 1983, DSC offers reliable, high-level support for even the most complex projects.

Conclusion

In a highly competitive global market, embracing FEA simulation for design validation is essential for survival and growth. The path to superior productivity and serious cost reduction is paved with data and precision engineering.

If you are a manufacturer looking to accelerate projects, ensure superior product quality, and strengthen your position in the Ontario manufacturing landscape, contact the industrial engineering experts at DSC.